Battery Grid Pasting Belt Manufacturers in India - Premier Belting Solutions

Premier Belting Solutions is a well established Battery Grid Pasting Belt manufacturers in India and suppliers in India. Over the years, the company has focused on refining belt materials and integrating new-age surface technologies to support high-speed and high-accuracy pasting processes. Today’s battery industry requires belts that can keep up with automation, provide stable adhesion, and ensure uniform paste distribution, and this is where our technologically advanced solutions play a vital role.

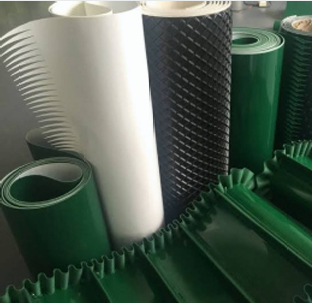

Types of Battery Grid Pasting Belts

As a leading Battery Grid Pasting Belt Manufacturers in India, we are providing the best quality Battery Grid Pasting Belt such as:

- PVC (Polyvinyl Chloride) Belts:

PVC belts are designed for reliable grip and uniform coating performance during the pasting process. Modern PVC belts now come with anti-static layers and enhanced thermal resistance to withstand continuous operation in automated pasting lines. Their smooth surface finish helps maintain precise paste distribution on both small and large grid sizes.

- PU (Polyurethane) Belts:

PU belts provide excellent flexibility and abrasion resistance, making them ideal for long-duration cycles. With advancements in polyurethane formulations, these belts now offer higher tensile strength along with micro-textured surfaces for controlled paste movement. They are widely used in battery manufacturing units aiming for high-speed, precision-driven operations. - Silicone Belts:

Silicone belts are suitable for high-temperature applications and ensure superior non-stick performance. The latest silicone belts feature heat-tolerant additives and enhanced elasticity that support smoother grid handling. Their advanced hygienic surfaces make them ideal for clean and controlled pasting environments. - Special Coating Rubber Belts:

Rubber belts with special coatings are developed for heavy-duty pasting requirements where durability and chemical resistance are essential. Updated versions of these belts include nano-coating technologies that resist corrosion and reduce paste adherence. These belts work exceptionally well in fast-paced production where consistent performance is crucial. - Composite Belts:

Composite belts combine multiple materials to enhance strength, surface stability, and thermal performance. Advanced composite structures now include fiber-infused layers that support superior load handling and reduced belt stretching. They are widely used in modern battery plants aiming for higher productivity with minimal downtime.

PVC (Polyvinyl Chloride) Belts:

PU (Polyurethane) Belts

Special Coating Rubber Belts

Composite Belts

Technical Specifications:

| Specification | Details |

|---|---|

| Belt Material | High-grade PU / PVC composite |

| Surface Finish | Smooth, non-stick, anti-adhesive |

| Working Temperature | 0°C to 120°C (depending on material blend) |

| Tensile Strength | High-tensile core for stable pasting operations |

| Abrasion Resistance | Enhanced wear layer for long service life |

| Chemical Resistance | Resistant to battery paste, acids, and additives |

| Belt Thickness | Typically 2.0–6.0 mm (customizable) |

| Tracking System | Precision-engineered for stable and accurate tracking |

| Joint Type | Finger joint / endless splice options |

Features of Battery Grid Pasting Belts

One of the leading Battery Grid Pasting Belt Suppliers in India, our all-types of Battery Grid Pasting Belt are included with new technological formulations such as:

| Feature | Key Benefit | Technology Used | Operational Advantage | Impact on Output |

|---|---|---|---|---|

| High Thermal Resistance | Withstands elevated temperatures | Heat-stabilized polymers | Maintains surface integrity | Consistent paste application |

| Adhesion & Surface Control | Balanced grip and clean release | Specialized textures + digital finishing | Prevents buildup and uneven coating | Uniform, high-quality grids |

| Anti-Static Properties | Reduces particle attraction | Advanced anti-static layering | Cleaner handling and safer operations | Lower contamination risk |

| Durability & Stability | Flexible, stable, and wear-resistant | Reinforced layers + protective coatings | Resists deformation and abrasion | Longer belt life in high-volume line |

Benefits of Battery Grid Pasting Belts

- Improved Production Efficiency:

Advanced belts reduce friction, enhance paste control, and support higher machine speeds. These improvements significantly boost overall production output in battery manufacturing facilities. Faster cycle times lead to increased productivity without compromising quality. - Enhanced Battery Plate Quality:

The belts’ advanced surfaces help achieve uniform paste thickness, resulting in better-performing battery plates. This contributes to longer battery life and improved charging efficiency. Manufacturers benefit from fewer defects and higher product reliability. - Reduced Maintenance Requirements:

New materials and coatings make the belts more resistant to wear, temperature shifts, and chemical exposure. This minimizes the need for frequent replacements or downtime for maintenance. As a result, production lines operate more smoothly and cost-effectively. - Energy-Efficient Operation:

The belts are engineered to reduce drag and enhance smooth movement across guides and rollers. This reduction in friction contributes to lower energy consumption throughout the manufacturing process. Energy savings accumulate over time, making the production line more eco-friendly.

Applications of Battery Grid Pasting Belts

Being the best Battery Grid Pasting Belt manufacturers in India, our all types of Battery Grid Pasting Belt are included with new feature and highly used in multiple applications such as:

- Automotive Battery Manufacturing:

These belts are widely used in producing automotive batteries where high consistency is required for better starting power and durability. Modern belts support improved speed control and precise paste application, ensuring quality output. Their reliability is essential for meeting the demands of large vehicle battery manufacturers. - Industrial Battery Production:

Industrial batteries used in backup systems, forklifts, and heavy equipment rely heavily on precise grid pasting. The belts’ advanced chemical-resistant surfaces ensure stable performance in various industrial applications. This leads to stronger battery plates capable of heavy-duty usage. - Inverter and Home Battery Manufacturing:

The belts play a crucial role in producing inverter batteries that require accurate paste layering for long service life. Their refined surface textures ensure efficiency even in small and medium-scale production units. These belts support consistent operation in automated and semi-automated pasting machines. - Solar and Renewable Energy Battery Production:

Batteries used in solar applications demand high-quality grid plates for efficient charge cycles. Advanced grid pasting belts help maintain uniform paste distribution in high-energy battery designs. Their reliability enhances the performance and lifespan of renewable energy storage systems.

Premier Belting Solutions is a prominent Battery Grid Pasting Belts manufacturers in India and suppliers in India. Our continuous focus on innovation, material science, and performance optimization ensures that every belt contributes to improved efficiency, superior battery plate quality, and long-term production reliability. Contact us today for more information!

FAQs

They ensure accurate paste application and improve the overall quality of battery plates.

Their lifespan varies depending on usage but is significantly longer due to improved materials.

Yes, they are engineered to perform efficiently in fast-moving and automated systems.

They are compatible with various grid sizes and materials used across battery production.

Let's Check Our Features

We utilizes advanced materials and designs to enhance conveyor belt performance and durability.

Premier Belting Solutions ensures timely delivery to minimize downtime and maintain operational efficiency for clients.

We leverages advanced materials for durable, efficient conveyor belts. We ensure timely deliveries and provide 24/7 expert support to minimize downtime.