PU Sidewall Conveyor Belt Manufacturers in Pune | Premier Belting Solutions

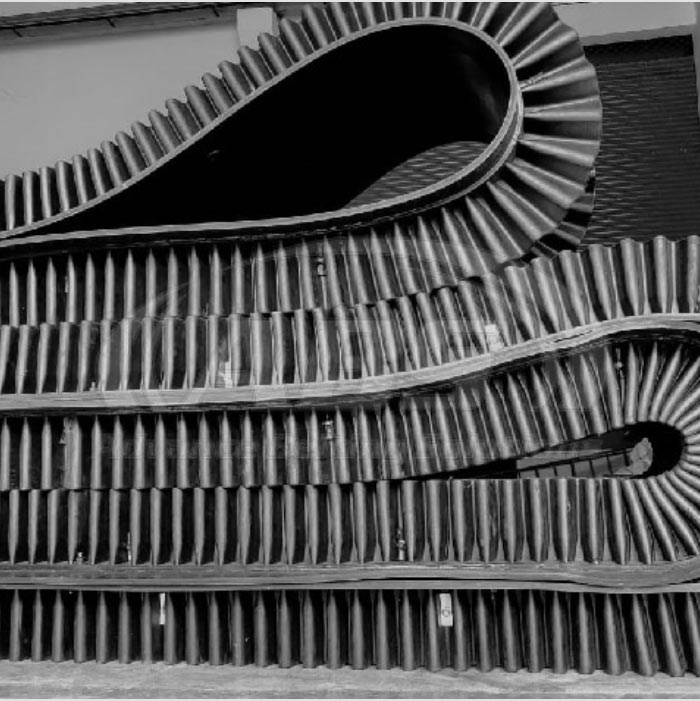

Premier Belting Solutions is a leading PU Sidewall Conveyor Belt Manufacturers in Pune and Suppliers in Pune. With a strong commitment to innovation, the company focuses on producing conveyor belts that enhance productivity, reduce downtime, and ensure long-lasting reliability across demanding environments. Our PU sidewall belts are designed to handle steep inclines, delicate materials, and high-throughput operations where efficiency and precision matter the most.

Types of PU Sidewall Conveyor Belts

A well-known PU Sidewall Conveyor Belt Manufacturers in Pune, we are providing the best quality PU Sidewall Conveyor Belt such as:

- Straight Sidewall Belts

Straight sidewall belts are ideal for vertical or inclined conveying where materials must remain controlled throughout the process. New advancements include reinforced PU structures that increase load stability without adding weight to the system. These belts are extensively used for food, pharmaceutical, and packaging applications requiring contamination-free handling.

- Sidewall Belts with Cross Cleats

Sidewall belts with cross cleats ensure extra support for granular, powdered, or free-flowing materials on steep angles. Modern versions integrate heat-welded cleats that offer superior adhesion, preventing slippage even under continuous operation. These belts are commonly favored in agriculture, recycling, and bulk-material processing sectors. - Scoop Cleat Sidewall Belts

Scoop cleat sidewall belts are engineered to collect and elevate materials efficiently, especially when dealing with fragile products. Advanced belt designs feature angled scoop patterns that reduce product damage and improve carrying capacity. They are widely used in applications like snacks, grains, seeds, and delicate industrial components. - Sidewall Belts with C-Shaped Cleats

Sidewall belts with C-shaped cleats offer enhanced grip and containment for lightweight and soft materials. Newer versions include flexible PU compounds that maintain shape stability even at high conveying speeds. These belts are preferred in sectors where material positioning and controlled movement are essential. - Sidewall Belts with T-Shaped Cleats

T-shaped cleat belts ensure maximum load support and prevent backflow of materials during steep conveying. Technological updates include precision-molded PU structures that improve mechanical strength while keeping the belt lightweight. Industries dealing with heavy powders, chemicals, and granules rely on these belts for consistent performance.

Straight Sidewall Belts

Sidewall Belts with Cross Cleats

Scoop Cleat Sidewall Belts

Sidewall Belts with C-Shaped Cleats

Sidewall Belts with T-Shaped Cleats

Technical Specifications

| Specification | Details |

|---|---|

| Belt Material | Polyurethane (PU) |

| Belt Thickness | 1.2 mm – 3.0 mm |

| Sidewall Height | 20 mm – 120 mm |

| Shore Hardness | 85–95 Shore A |

| Temperature Resistance | –20°C to +80°C |

| Tensile Strength | High tensile PU with fabric reinforcement |

| Surface Finish | Smooth / Matt / Anti-slip |

| Conveying Angle | Up to 90° depending on sidewall type |

| Food Compliance | FDA/EU-approved (food-grade variants) |

Features of PU Sidewall Conveyor Belts

One of the leading PU Sidewall Conveyor Belt Suppliers in Pune, our all-types of PU Sidewall Conveyor Belt are included with new technological formulations such as:

- High-Strength PU Construction

The belts are built using premium-grade polyurethane that offers exceptional tensile strength and flexibility. New manufacturing technologies enhance resistance against abrasion, oils, and chemical exposure. This results in longer operational life and reduced maintenance needs. - Heat-Welded Sidewalls and Cleats

Modern PU belts feature heat-welded joints to ensure seamless bonding between the base belt and sidewalls. The updated welding process eliminates weak points, improving durability under continuous load stress. Such construction supports faster conveying operations without risk of detachment. - Hygienic and Food-Safe Design

Advanced PU compounds meet strict hygiene standards for industries handling edible or sensitive materials. The smooth, non-porous surface prevents bacterial buildup and makes cleaning easier. This feature ensures product safety throughout the conveying cycle. - Lightweight Yet High Load Capacity

Advanced PU compounds meet strict hygiene standards for industries handling edible or sensitive materials. The smooth, non-porous surface prevents bacterial buildup and makes cleaning easier. This feature ensures product safety throughout the conveying cycle.

Applications of our PU Sidewall Conveyor Belt

Being the best PU Sidewall Conveyor Belt manufacturers in Pune, our all types of PU Sidewall Conveyor Belt are included with new feature and highly used in multiple applications such as:

- Food Processing Industry

PU belts handle items like snacks, grains, frozen goods, and bakery ingredients with high hygiene standards. The smooth, non-porous surface prevents contamination and supports easy cleaning. They help maintain quality and safety throughout the food handling process. - Pharmaceutical and Chemical Plants

These belts are suitable for powders, tablets, granules, and sensitive chemical materials due to their chemical resistance. Advanced PU technology ensures no reaction with transported products, maintaining purity. They support strict compliance standards in regulated industries. - Packaging and Sorting Units

PU sidewall belts support fast movement of packaged goods without damaging edges or labels. Their stability and accurate carrying control enhance automation efficiency. Packaging lines benefit from reduced errors and higher throughput. - Agriculture and Grain Handling

Farm products like seeds, grains, and fertilizers are handled efficiently with scoop-cleat and cross-cleat PU belts. Their slip-resistant design ensures safe transport even during steep conveying. This helps minimize material loss and improve overall productivity.

Premier Belting Solutions is a genuine PU Sidewall Conveyor Belts Manufacturers and Suppliers in Pune.The integration of updated PU technology, precision engineering, and application-specific designs ensures superior performance across diverse sectors. Choosing these belts provides industries with a long-lasting, safe, and future-ready conveying solution that enhances productivity at every stage. Contact us today for more information!

FAQs

They are more durable, hygienic, and suitable for steep conveying applications.

Yes, their hygienic and non-porous surface makes them ideal for food-grade applications.

Yes, the advanced cleat and sidewall design ensures secure conveying at steep angles.

No, their durable construction significantly reduces maintenance needs.